Solution Description

Introduction

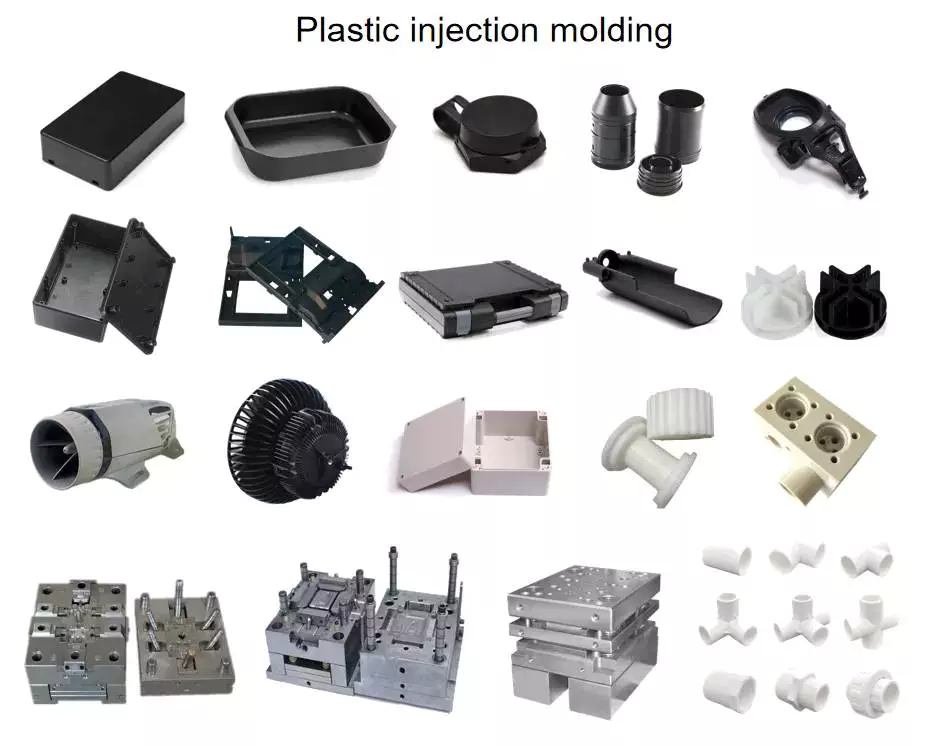

As a leading plastic injection molding firm, Moldor Plastic has reached wealthy ordeals of design, engineering, and manufacturing benefit-included plastic mould and supplying molded items to consumers all more than the planet. Equipped with state of the artwork equipment and expert personnel, we provide you the substantial-good quality goods at very aggressive value.

Our plastic elements are commonly utilized in Auto Equipment, Electronics, Household appliances, Healthcare Devices, Match Players, Mechanical gadgets and other fields.

Good quality Initial & Support First & CUSTMER Very first is our purpose,MAKE Every Undertaking A Accomplishment is our mission.We sincerely hope to be your dependable associate for prolonged-termcooperation.

Solution Information

| Mildew Shaping | Tailored Plastic Injection Molding |

| Plastic Material | PP, Laptop, PS, POM, PE, Abs, and so on. as per customers’ requierment |

| Surface Finish | Mirror Polish, Texture, Sandblast, Mate, Spray Paint, Silk monitor and and many others. |

| Plastic Materials | PP, Laptop, PS, POM, PE, Abdominal muscles, etc. as for every customers’ requierment |

| Shipping Time | five-8 times right after samples verified |

| Shade | Offer Pantone Shade Code or sample |

| Packaging | Regular Export Carton |

Custom made Your Very own Plastic Components in MOLDOR PLASTIC !

In accordance to your drawings or samples, we can provide 1-end solutions service from planning, prototyping, molds

making, processing, spraying, assembling, inspecting, packaging to offering, every little thing will be managed to the

smallest depth.

If you have items or suggestions that need injection mould & molding, Moldor Plastic would like to serve you. Our well-informed engineers and designers will supply recommendations on how to manufacture your product to let for a professional

seem as effectively as for simplicity of producing.

Remember to kindly e-mail us your inquiry, and our specialist team is dedicated to delivering individual services at the

cheapest achievable rates to you.Your any inquiry is welcomed and will be replied before long.

Associated Merchandise

MOLDOR PLASTIC Benefit:

In-home mould design and building capabilities to enhance perform effectiveness.

NDA agreement can be signed to shield customers’ idea

and design.

Skilled income staff. Great communication abilities and

right after provider.

Specialist layout group, mildew maker engineer. OEM/

ODM provider.

Professional QC and R&D groups to assure high quality.

Supply on time.

We can do far more than you expected…

1. Production experience for in excess of 15 years.

two. Personalized designs and services are recognized.

Expert layout crew and engineering crew offer

complex help.

three. Manufacturing process manage.

4. Small volume generation or mass creation is obtainable.

5. Qualified personnel and skilled QC group to guarantee the

product top quality.

6. Inspection report and material take a look at certificates are

accessible on requests.

7. Regular: HASCO or as customer’s need.

……

Manufacturing unit Functionality

Our Support

Phase 1: Item Style: We give product style provider as customers’ request.

Phase 2: Mold Design and style: We communicate & exchange the depth info with our buyers to make a great mildew design and style.

Action 3: Mould Making: Manufacturing in-property, we ship the mould processing photos and videos to buyers.

Phase 4: Mass Manufacturing: We start off plastic injection areas production right after customers verify samples.

Phase 5: Assembly: We can offer assembly provider as customers’ requests.

Action 6: Price extra Provider: Accessible, these kinds of as display screen printing, plating, custom made packaging and and so on.

Packaging & Shipping and delivery

FAQ

Q1:Are you a buying and selling business or manufacturing unit?

A1:We are manufacturing facility.

Q2:What kind of information is needed for quoting a molding undertaking?

A2:Please ship your drawings or sample to us.

Q3:How extended do you just take to construct a mould?

A3:The production timeline depends on your certain needs, normally the lead time is twenty five-45days.

This autumn:How little or big of a plastic part will you produce?

A4:Our machine capabilities protect a assortment from 60-ton to 500-ton clamping forces.

Q5:What sort of steel do you use for plastic moldings?

A5:We can use any sort of metal appointed by client or well-known in the marketplace.Such as P20,718,8407,NAK80,H13,S136,

DIN 1.2738,DIN 1.2344,and many others.

Q6:What varieties of resources can be molded by your injection merchandise?

A6:Polystyrene,Abdominal muscles,PET,TPR,TPU,PVC,Nylon,Acetal,Polypropylene,Polyethylene, Polycarbonates and and so forth.

Q7:Do you offer you secondary support these kinds of as assembly, packaging or portray?

A7:Of course,such as assembly, painting, tapping, ultrasonic welding, trimming, sorting, customized packaging and etc.

Q8:If I have an current tooling, could you use it to mould my task?

A8:Most definitely, if present tooling is obtainable, we can use them.

Q9:Can you mildew close to inserts or metal components?

A9:We can do insert molding with just about any steel and non-metallic factors.

|

US $0.8-1.5 / Piece | |

500 Pieces (Min. Order) |

###

| Plastic Type: | Thermoplast |

|---|---|

| Plastic Form: | Granule |

| Molding Method: | Injection Molding |

| Plastic Color: | Black, Red, Yellow, White, or Others |

| Mold Runner: | Cold or Hot Runner |

| Surface Finish: | Polish, Texture, Matt, Smooth, Can Be Customized |

###

| Customization: |

Available

|

|---|

###

| Mold Shaping | Customized Plastic Injection Molding |

| Plastic Material | PP, PC, PS, POM, PE, ABS, etc. as per customers’ requierment |

| Surface Finish | Mirror Polish, Texture, Sandblast, Mate, Spray Paint, Silk screen and etc. |

| Plastic Material | PP, PC, PS, POM, PE, ABS, etc. as per customers’ requierment |

| Delivery Time | 5-8 days after samples confirmed |

| Color | Provide Pantone Color Code or sample |

| Packaging | Standard Export Carton |

|

US $0.8-1.5 / Piece | |

500 Pieces (Min. Order) |

###

| Plastic Type: | Thermoplast |

|---|---|

| Plastic Form: | Granule |

| Molding Method: | Injection Molding |

| Plastic Color: | Black, Red, Yellow, White, or Others |

| Mold Runner: | Cold or Hot Runner |

| Surface Finish: | Polish, Texture, Matt, Smooth, Can Be Customized |

###

| Customization: |

Available

|

|---|

###

| Mold Shaping | Customized Plastic Injection Molding |

| Plastic Material | PP, PC, PS, POM, PE, ABS, etc. as per customers’ requierment |

| Surface Finish | Mirror Polish, Texture, Sandblast, Mate, Spray Paint, Silk screen and etc. |

| Plastic Material | PP, PC, PS, POM, PE, ABS, etc. as per customers’ requierment |

| Delivery Time | 5-8 days after samples confirmed |

| Color | Provide Pantone Color Code or sample |

| Packaging | Standard Export Carton |

Design Considerations for Injection Molded Parts

There are many factors to consider when designing a component for injection molding. These include design factors, materials, overhangs, and process. Understanding these factors will make it easier to choose the right part for the application. In this article, we’ll go over several of the most common design considerations.

Design factors

To get the best results from your injection molded parts, you must ensure that they meet certain design factors. These factors can help you achieve consistent parts and reduce cost. These guidelines can also help you to avoid common defects. One of the most common defects is warping, which is caused by the unintended warping of the part as it cools.

To get the best results from your injection molded parts, you must ensure that they meet certain design factors. These factors can help you achieve consistent parts and reduce cost. These guidelines can also help you to avoid common defects. One of the most common defects is warping, which is caused by the unintended warping of the part as it cools.

When designing injection molded parts, the draft angle is critical. Increasing the draft angle allows the part to emerge cleanly from the mold and reduces stress concentration. This can improve the part’s function and speed up the production process. In addition, it ensures a uniform surface finish. Incorrect draft angles can result in parts that are not functional and can cost you money. If your product team doesn’t pay attention to these design factors, they could end up destroying expensive molds and producing a high number of rejects.

Ribs are another design factor that should be taken into consideration. Rib height should be less than three times the thickness of the part’s wall. This will prevent sink marks and minimize the chances of the ribs sticking inside the mold.

Materials

There are many options when it comes to materials for injection molded parts. Choosing the right material will affect how well it performs in your particular application. If you need a large part to be flexible and sturdy, then a plastic with good flow properties will work best. Injection molded plastics come in a variety of different resins. Choose the one that best meets your application’s needs, considering its main functionality and the desired appearance. You may also want to choose a material that is UV resistant, heat resistant, flexible, and food safe.

Polymers that are suitable for injection molding include polycarbonate and polypropylene. These materials are flexible and strong, and can be used to create parts with high-level details. These materials are also lightweight and inexpensive. Despite being flexible, they are not suitable for high-stress applications.

During the molding process, the injected material must be cooled, otherwise it will expand again. This is why you need to keep the temperature of the mould at 80 degrees Celsius or less.

Process

Injection molding is the process of creating plastic parts. The plastic is melted in a mold and then forced to cool. It then solidifies into the desired shape. During the cooling process, the plastic can shrink, so it is important to pack the material tightly in the mold to prevent visible shrinkage. When the mold is completed, it cannot be opened until the required cooling time has passed. This time can be estimated based on the thermodynamic properties of plastic and the maximum wall thickness of the part.

The mold must be precisely designed and tested. The process can be repeated many times, which makes it ideal for mass production. It is also one of the fastest ways to scale production. The more parts a mold can produce, the lower its cost per piece. This is one of the benefits of injection molding.

Injection molding parts are used for many industries, including appliances, electronics, packaging, and medical devices. They can be made to have complicated shapes.

Overhangs

Overhangs are areas of extra material that surround the surface of an injection molded part. This extra material is typically made of inexpensive material that is edged or glued on the part’s surface. The overhang material can be easily separated from the blank using a simple cutting process.

Overhangs are areas of extra material that surround the surface of an injection molded part. This extra material is typically made of inexpensive material that is edged or glued on the part’s surface. The overhang material can be easily separated from the blank using a simple cutting process.

The amount of material needed for an overhang is dependent on the shape of the part and the amount of surface area. Generally, an overhang is less than 15 percent of the cost of the part. Usually, the material used should be able to fulfill the overhang’s function and differentiate it from the material in the form flachen area.

Overhangs on injection molded parts should be avoided because they may cause the design to become unstable. To avoid this problem, consider designing your part so that the sides and edges are parallel to one another. This will help ensure that the part will be free of undercuts and overhangs.

Overhangs on injection molded parts can be avoided by ensuring that the parts are designed with tolerances in mind. For example, an overhang in an injection molded part can cause a mold to have an overhang that is too small for the machine. This can cause problems in the manufacturing process, and it can result in a costly mold.

Cost

Injection molding costs can vary depending on the complexity of the part, the size and the type of plastic. Parts with complex geometries may require additional design work and tooling. Larger parts can also cost more than small ones. The amount of time spent designing and producing them is also important.

To reduce the cost of injection molding, a manufacturer must consider two major factors: tooling and the material used. The plastic used for injection molding has several different properties, which will impact the part price. For instance, plastics with a lot of glass fibers will reduce the amount of time necessary to repair the mold. Another factor to consider is the thermal properties of the material.

The next major factor in the cost of injection molded parts is the material of the injection mold. While most of these molds are made of steel, the type and grade of steel used is important. Injection molds are also required to have nearly wear-free interior cavities. This is necessary to maintain tight tolerances.

Another factor that contributes to the cost of injection molded parts is the cost of bulk material. This material costs money and requires expensive electricity to process. Typically, the more parts you produce, the lower the cost per pound. Storage of bulk material is also a significant expense. Therefore, a quicker cycle time will reduce storage costs.

Reliability

While manufacturing involves some degree of variation, the variation should be within acceptable limits. This is essential if you want to produce high-quality, dimensionally stable parts. A reliable manufacturing process involves precise control over mold tooling and part design. It also requires repeatability in both quality and production processes.

A reliable injection molding process also focuses on detecting defects early in the production process. Invisible hazards, such as air pockets, mold materials compromised by overheating, and more, can lead to failure. These defects will most likely not be discovered by simple visual inspection and may not come to light until after warranty claims are filed from the field. By finding the defects in the early stages, manufacturers can maximize productivity and reduce costs by minimizing the number of replacement parts needed.

The process of building a custom mould for plastic components is highly skilled. A perfect mould will eliminate potential defects and ensure that the production process is reliable. Traditionally, this process relied on trial and error, which added time and money to the production process.

Design for manufacturability

When designing injection molded parts, it is imperative to keep in mind their manufacturability. Injection molding allows for complex geometries and multiple functions to be combined into a single part. For example, a hinged part can have a single mold that can produce two different halves. This also decreases the overall volume of the part.

When designing injection molded parts, it is imperative to keep in mind their manufacturability. Injection molding allows for complex geometries and multiple functions to be combined into a single part. For example, a hinged part can have a single mold that can produce two different halves. This also decreases the overall volume of the part.

Injection molded parts do not typically undergo post-processing. However, the mold itself can be finished to various degrees. If the mold is rough, it can cause friction during the ejection process and require a larger draft angle. Detailed finishing procedures are outlined by the Society of Plastics Industry.

The process of designing injection molds is very exacting. Any errors in the mold design can lead to out-of-spec parts and costly repair. Therefore, the process of Design for Manufacturability (DFM) validation is a key step early in the injection molding process. Fictiv’s DFM feedback process can identify design challenges and provide early feedback to minimize lead times and improve quality.

The surface of an injection molded part can develop sink marks, which occur when the material has not fully solidified when it is ejected from the mold. Parts with thick walls or ribs are more prone to sinking. Another common defect in plastic injection molding is drag marks, which occur when walls scrape against one another during ejection. In addition to sink marks, parts with holes or exposed edges can form knit lines.

editor by czh 2022-12-17